At Ubiquity Steel Detailing Private Limited, we provide end-to-end steel detailing solutions with accuracy, efficiency, and compliance at the core.

Our steel detailing client coordination process ensures smooth communication and flawless project execution from the very first client inquiry to final project handover. This workflow includes requirement analysis, proposal preparation, contract award, design review, detailed 3D modeling, internal quality checks, fabrication support, and project closeout. Throughout every stage, we prioritize clarity, precision, and adherence to industry standards, providing regular updates and transparent communication to achieve the highest quality deliverables.

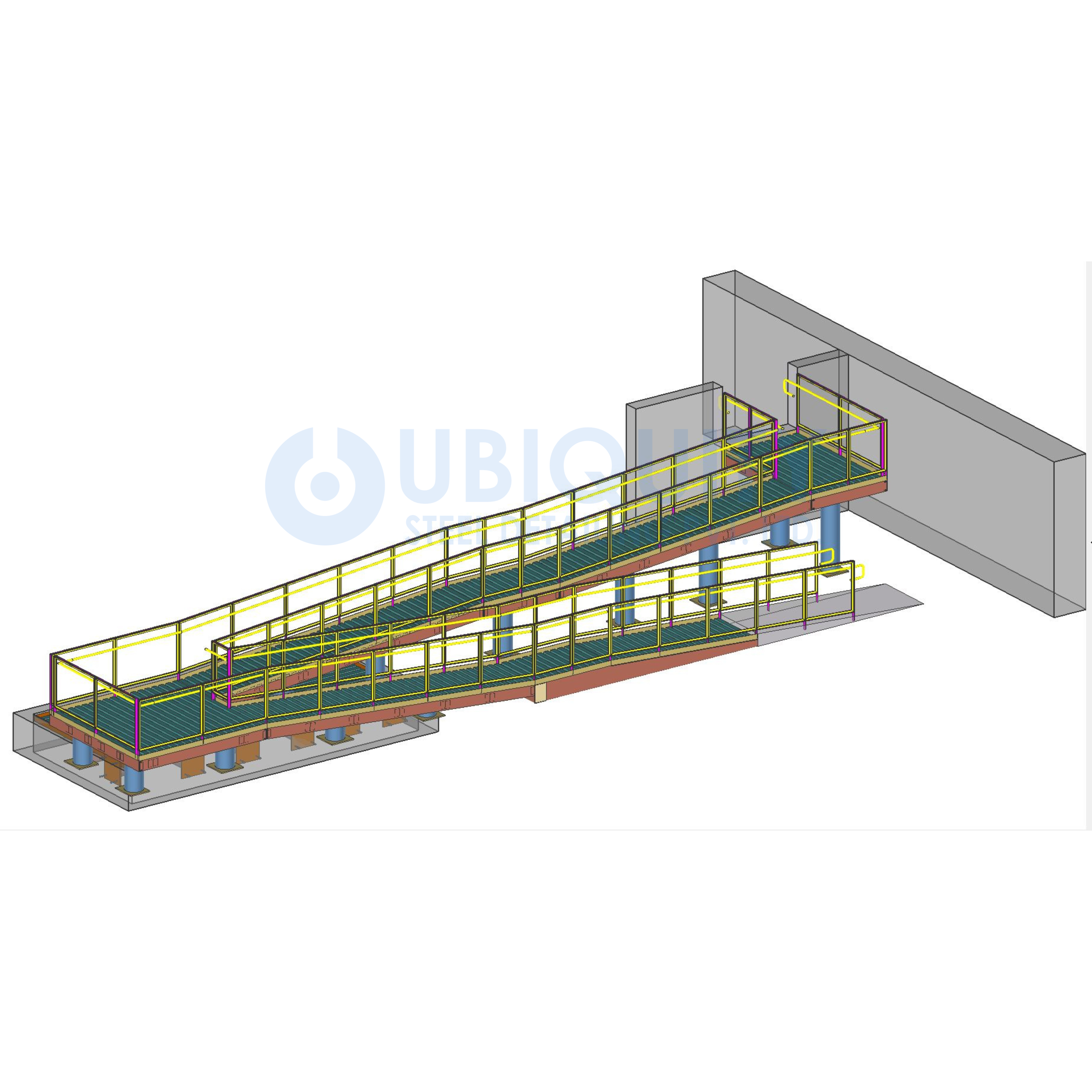

We produce detailed shop drawings for all structural steel components including: Beams, columns, braces, Stairs, ladders, and handrails, Erection drawings with plans, elevations & sections, Moment and shear connections.

Our team provides precise shop drawings and 3D models for a wide range of miscellaneous steel elements, including: Stairs and Stair Stringers, Handrails and Guardrails, Ladders and Cage LaddersCanopies, Supports, Brackets.

We deliver clean, fabrication-ready shop drawings with: Accurate dimensions and BOMs (Bill of Materials), CNC data and DXF files (on request), Bolt and weld details, Field and erection markings.

We assist with: Coordinating RFIs and markups, Integrating design changes, Resolving clashes and constructability issues, Smooth coordination with engineers, fabricators, and GC teams.

We provide accurate and detailed material take-offs to help fabricators, contractors, and engineers estimate costs, plan procurement, and optimize project timelines.

We use leading steel detailing software including: SDS/2, Tekla Structures, BlueBeam, Advance Steel. Our output is fully customizable to your shop and project requirements.